Adaptive Gaming Switch Holder

Making video games accessible by foot.

@ Greater Boston Intercollegiate Assistive Technology Hackathon 2025

Role

Product Designer

+ Kristtyan Tran (Occu. Therapist), Dylan Prudente (Product Designer), Davide Mirza (Product Designer), Hamza and mom (Co-Designer)

Skills

End to end design, laser cutting, CAD (Solidworks) & 3D printing

Timeline

A week-long hackathon + two days iterating

TL;DR

We created a switch holder for Hamza to play video games with his feet. I got to hand it to him personally, see his face light up as he kicked the switches, and take his feedback into another iteration.

I’m most proud of our design thinking process, meaningful touchpoints, and iterative design. Here, I’ll give you a boost.

The Challenge

How might we make foot-gaming more convenient and responsive for Hamza?

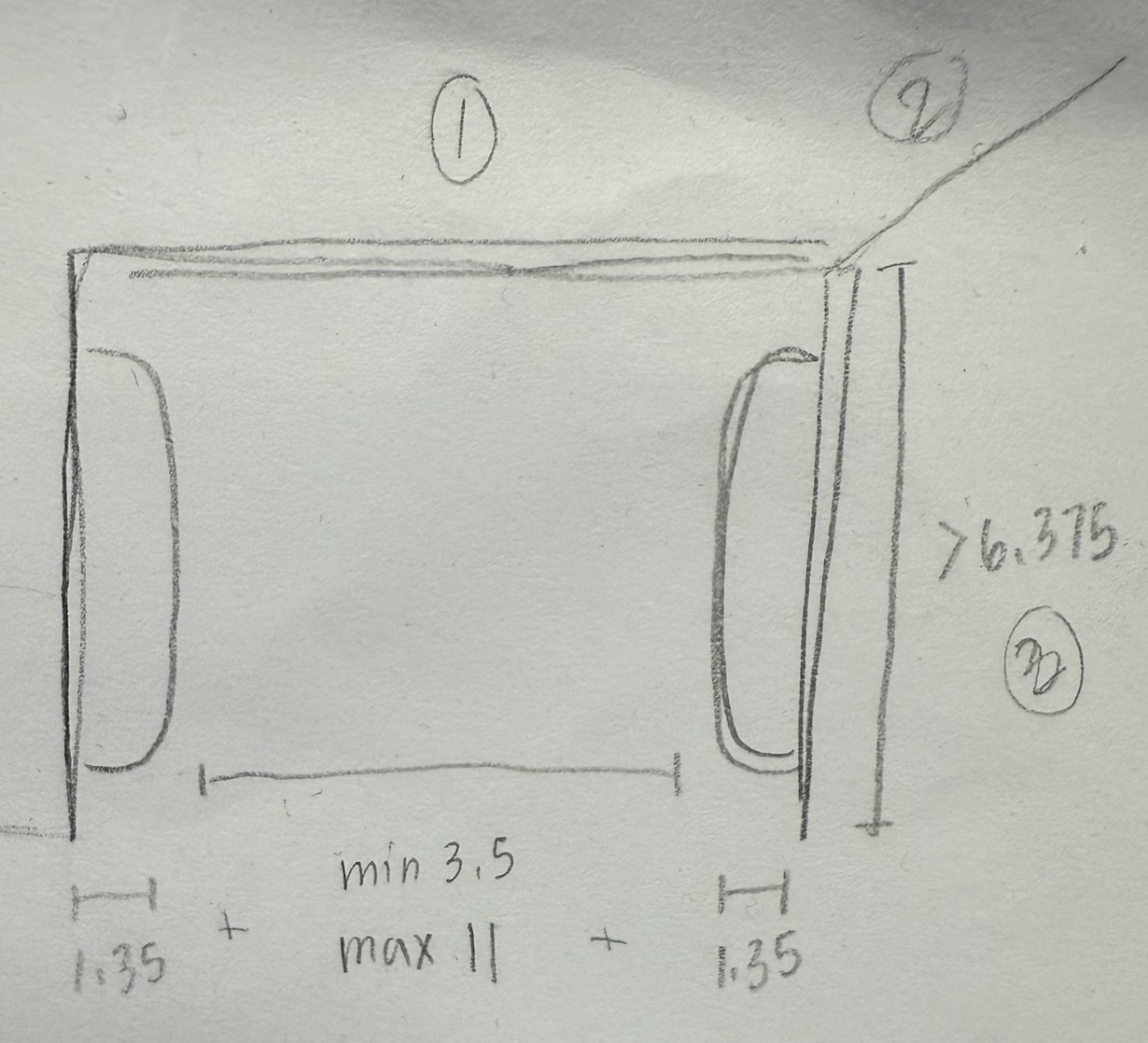

We were paired with Hamza, an 11-year old boy with muscular dystrophy. He loves video games and plays them lying in his bed. He uses a video game controller for all buttons besides R1, R2, L1, and L2. Recently, he connected two switches (buttons) to the R1 and L1 functions of a video game controller using the PlayStation access controller. He hits these switches with his feet. We needed to make a device that holds those two switches steady but also makes room for an additional two switches on the inside of his feet.

Muscular dystrophy (MD) is a group of genetic diseases that cause muscle degeneration. People with MD typically have a small but precise range of fine motor skills, which is why Hamza’s fingers can reach some of the buttons, but not all of them.

Exploration & Learning

We developed our context through market research, task observation, and an interview.

Hamza’s original setup was two switches propped up with pillows and foam leaning against his bed railing. Set up this way, his switches fell over every time he kicked them and took a lot of adjustments to set up. He was happy to be gaming, but we could do better.

But we needed to know more. So we hopped on a call with Hamza and his mother, who showed us his gameplay live and answered a long list of questions we had about Hamza’s physical capabilities and environment, but also about his favorite color, blue, and superhero, Spiderman. (Good choice.)

Ideation

With exploration complete, we hit the drawing boards.

We developed a few key features that guided our brainstorming, but at this phase, no idea is a bad idea. We articulated our ideas and bounced off each other.

Hamza and his family originally suggested we make a U-shaped mount, where Hamza’s foot sits at the base of the U. We explored their idea (images 1 & 2) but decided upon an upside-down U or a U on its side instead (image 3). These orientations allowed for easier adjusting and prevented any material from irritating Hamza’s sensitive skin. What I learned here is to stay open-minded and evaluate every idea, no matter the owner, against our key features and needs. Reminds me of a quote from an automobile pioneer.

“If I had asked people what they wanted, they would have said faster horses.”

After numerous brainstorming sessions, paper prototypes, and taking every user need into account, we came to the idea that felt right. Now, with three days on the clock, it was time to get our hands dirty.

Manufacturing

We spent hours CAD modeling, laser cutting, assembling, and troubleshooting our product. All with Hamza in mind.

Final Prototype

We finished our device with a day to spare, so I hand-delivered it to Hamza on the last day of the hackathon.

Key Features (white circles represent switches)

Velcro panels = adjustable distance between switches

Velcro switches = adjustable positioning for each switch

Engraved board = excitement and personalization

Panel stack = easy storage and “H” easter egg

Our longboard design eliminated the need for bed railings to secure our device. We chose the design because we wanted the device to work on any bed at any length (as he grows) and because we wanted to leave open the possibility of using the device in a power chair or at a desk. They’re getting a new power chair soon and want to try our device in it!

Touchpoints make the difference; a little extra care goes a long way.

We gave Hamza,

a user manual and a video tutorial

a Dycem sticky mat for his access controller

extra velcro for additional switches

a handwritten note

and in-person set-up!

The most fulfilling moment of this hackathon was Hamza’s reaction to his new switch holder. He adored the Spiderman-Hamza board and said the device “feels so stable.” His mother and his helper appreciated how easy it was to store and set up the device. They didn’t even have to disassemble the panels; one person picked up the whole thing and placed it under Hamza’s bed in less than five seconds. This quick set up and break down time is crucial for everyday play.

Hamza played with the switch holder the entire time I was visiting his home. His mom told us that she hasn’t been able to get him off the device since we dropped it off.

Iterating and Improving

A month later, during Tufts finals week, we got the news. Our switch holder broke.

But hey. Stick around. Something good, better, comes out of this one.

The Bad

One of the four panels snapped off its attachment, which also cracked. Hamza was applying more force to the panels than we had anticipated; he had started using a plastic foot brace. We didn’t have any funding for materials. And my teammates needed to focus on finals, so I was flying solo on this iteration.

The Good

Our broken device was still usable with a small support. And now we had more information to improve the design; we knew that joint was weak but hadn’t known how to make it better during the hackathon. Most importantly, Hamza’s OT (my AT professor) told me that I could not take our device away from Hamza for repairs.

She said his world would be destroyed even if it was just a day without it; that’s what our device meant to Hamza.

Our biggest problem was the weak glue join. What if we could eliminate that weakness altogether?

3D printing was my solution. It’s free for Tufts students and makes parts so easy to replicate in case of future damage. But most importantly, it eliminates the weak join and even strengthens the build if oriented against the print layers. I CAD modeled a new panel design on Solidworks and set some prints.

Key Features

Problems and how we fixed them

Can’t take device for repairs? New panels that still work with the Spiderman board

Attachment might’ve cracked from strong Velcro? Thinner attachment strip plus lip for removal

Hard foot brace increases force? 3D print layers against the force

Panel breaking off at attachment point? 3D print eliminates joint altogether, filet increases strength

I had the new iteration ready to ship in two days. (The day I moved out of Tufts for the summer, actually.) We’re waiting to hear back from Hamza and his family on the new panels. I’ll be back with updates.

Reflection

Hamza’s switch holder taught me to embody my user’s needs; even if it meant changing the user’s suggested design for the device

This project was my first real experience taking a product to the home of the user, receiving real-life feedback (felt way different from a usability test), and developing a new iteration. Making Hamza’s switch holder truly became a deep passion project for me. And my teammates turned into really cool friends. :-)